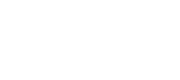

Avoid These 5 Common API Mistakes for Smoother Logistics Operations

- #1 Mistake: Not updating older API specifications

- #2 Mistake: Losing sight of the routine operations automation

- #3 Mistake: Not planning ahead

- #4 Mistake: Doing everything on your own

- #5 Mistake: Trying to provide support independently

- FAQ about common API mistakes in logistics

- Bottom line

So, as a logistics provider, you decided to conduct API integration of your systems with client software to ensure seamless data exchange. At first glance, this process seems straightforward—all you need is to involve developers and follow the API specifications exactly as described.

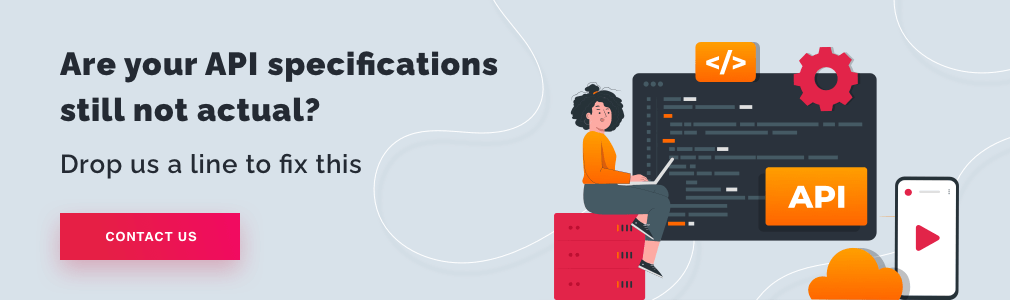

However, our six years of experience in logistics show that things are not as simple as they may seem, despite the fact that API integration can indeed bring significant benefits to the logistics business. In our previous blog articles, we already described the possible integration options for TMS and WMS. Read them to determine which variants suit you and learn more about our use cases. In this article, we’re focusing on the most common API integration mistakes logistics providers encounter and provide tips on how to avoid them. Keep reading!

#1 Not updating older API specifications

The lack of up-to-date specifications is common API mistake developers make. For logistics service providers, the integration speed is crucial. Otherwise, they won’t be able to receive requests for warehouse and transportation operations. Any delays can cost LSPs revenue. However, in order to integrate rapidly with client systems, you need up-to-date specifications for your API.

Our experience shows that logistics providers frequently lack an up-to-date API description, which can significantly hinder the process. Once, a major client approached us from the logistics provider’s side. They started the API integration based on outdated specifications and spent an entire week on implementation. Only to find out that the description was no longer accurate. It resulted in wasted efforts, as well as developers’ time.

What should be done in such a situation? Since your IT department has a lot on its plate, it’s not always possible to keep track of the API specification’s accuracy. The best solution is to delegate such work to a certified partner. Your outsourcing vendor can monitor updates, release up-to-date specifications, and assist clients with integration if anything goes wrong.

Read also about 3 Amazon lessons logistics companies should follow.

#2 Losing sight of the routine operations automation

Logistics service providers overlook the potential for automation, especially when it comes to API integration. There are numerous routine and templated processes in business, and although they may not be feasible for a specific company.

Let’s consider medium and large-sized LSPs specializing in eCommerce logistics operations. In most cases, the platforms that need to be connected to your WMS or TMS are similar, repeating from client to client. Of course, you can implement integrations in each specific case, but what’s the point? It’s much easier and more efficient to develop ready-made plugins that connect your systems with client platforms.

To choose the platform for which you need to develop a plugin, we recommend following this scheme:

- Analyze your clients. Which platforms do they commonly work with?

- Gather statistics and compile a list of necessary plugins.

- Showcase the ready-made plugins on your website. This allows clients to quickly download and install them in their systems.

Why is it important to ensure the visibility of these plugins on your website? We have a case for you. When collaborating with a logistics provider, we discovered that they already had a ready-made plugin for integrating with client systems. However, it was buried deep within their website, so clients often didn’t even know it existed.

If you have many clients or insufficient data for research, it’s better to engage a third-party IT service provider. For example, as part of this service, Coreteka conducts business analysis to identify the most popular systems on the client’s side. Afterward, we handle the development of plugins. Moreover, your IT service provider can assist clients with plugin installation and provide support to ensure their proper maintenance.

#3 Not planning ahead

This is one of the most common API development mistakes for medium-sized logistics providers that are still developing on the market. Often, such companies do not understand their customers and how they’re going to evolve in the future. That’s why they develop unnecessary features and ignore the truly important ones.

Let us be honest: if you plan to work with small clients, you don’t need API integration. You need a simpler and easily implementable tool that will help facilitate data exchange. In this case, ready-made online platforms will be suitable for you.

Here’s an example of proper development: one of our clients among logistics providers decided to focus on small eCommerce clients—companies that trade consumer goods. Instead of conducting API integration, the logistics provider initially included an interface option in their WMS functionality. Thanks to this feature, clients can submit requests for warehouse and transportation operations online. On the other hand, the logistics provider can track what is stored in their warehouse and in what quantities. Furthermore, they can extract all the necessary information and export it in the required format. We advocate for rationality. If you don’t need complex customer interaction, it’s better to think about how to simplify everything.

Sometimes, businesses misjudge their operations and initially include unnecessary functionality in their WMS. For example, we once encountered a logistics provider who purchased a ready-made solution for their business but overlooked the necessary functionality. Since they worked with small clients, there was a need to implement separate options for request submissions. When the company decided to purchase the necessary features, it turned out that the cost amounted to about $150.000. This was an unaffordable amount, whereas developing such a module from scratch would have been even more expensive.

But what if you didn’t initially include the right functionality in your WMS? Luckily, there are ready-made data exchange logistics platforms. One of them is developed by Coreteka—the Wareteka On-Demand platform. It is an online workspace that allows you to:

- Make orders and manage warehouse shipments in real-time

- Track and exchange order status data

- Monitor inventory levels

- Control goods movement

The Wareteka On-Demand interface can be easily integrated with popular WMS and ERP systems. You can obtain a ready-made solution at an affordable price.

#4 Doing everything on your own

When you’re a small company, doing everything on your own is relatively easy. But as the business grows, it appears a chaotic interaction between departments, making it difficult to understand which actions are truly important. This is especially noticeable in the case of outdated API specifications. Despite being a crucial component of customer service, IT departments of logistics companies often don’t have the resources to update outdated data.

Why not engage a certified partner on a long-term contract to address all these issues without burdening your own resources? This way, you can ensure that your clients receive quality support during system integration, and the specifications will always remain up to date.

#5 Trying to provide support independently

This issue is similar to the previous statement, and it’s one of the biggest API mistakes to avoid. After all, the logistics provider’s IT department should maintain the existing infrastructure. For example, your IT specialists need to ensure the WMS or TMS servers are running. In simple words, it’s like Maslow’s hierarchy of needs, where the IT department focuses on fulfilling basic requirements. Think about it: if the WMS server crashes, the entire warehouse operations come to a halt. That’s why we believe LSPs should be aimed at fulfilling basic needs. Everything else can be outsourced.

Currently, at Coreteka, we assist a logistics provider with supporting their customers. We take care of ensuring that any issues that arise don’t burden the client’s IT department. Moreover, to address these problems, we don’t require a technical specialist because we are the tech experts ourselves. Our team communicates with a manager. This significantly saves time that can be spent on maintaining a stable IT infrastructure for the warehouse.

FAQ about common API mistakes in logistics

In logistics, API serves as a connection between different systems. For example, you can integrate your Warehouse Management System with the client’s Enterprise Planning System. In such a way, it’s possible to establish seamless data exchange between two software, meaning you can quickly receive requests from your clients and process them.

Common problems with APIs in logistics include incompatible data formats between systems, lack of standardization and documentation, security vulnerabilities, reliability and performance issues, scalability limitations, API versioning challenges, limited error handling, and logging, complexity of integration across diverse systems, and inadequate post-integration support. These problems can lead to data errors, communication breakdowns, security breaches, operational disruptions, and difficulties in troubleshooting and maintaining integrations. Addressing these issues requires careful planning and robust API implementation.

When building API integrations, it is important to have clear objectives and understand the problem you are trying to solve. Compatibility and adherence to standards ensure seamless data exchange between systems. Scalability and performance optimizations ensure that integration can handle increased demands. Robust security measures protect sensitive data, while thorough documentation and support channels aid developers in implementing and troubleshooting the integration. Testing, versioning, monitoring, and effective communication contribute to a successful integration that aligns with business objectives and delivers value.

API integrations in logistics can encounter communication breakdowns, limited error handling, performance bottlenecks, compliance issues, vendor lock-in, lack of flexibility, poor performance monitoring, and incomplete data synchronization. These challenges can disrupt operations, lead to delays or inaccuracies in data transfer, hinder scalability and adaptability, and compromise regulatory compliance. Overcoming these issues requires effective communication, robust error-handling mechanisms, performance optimizations, compliance adherence, flexibility in integration options, proactive monitoring, and meticulous data synchronization practices.

API failures in logistics can occur due to connectivity issues, unauthorized access, scalability limitations, inadequate error handling, data format incompatibility, API versioning problems, performance bottlenecks, and service outages. These failures can disrupt data exchange, compromise security, hinder scalability, impede error resolution, cause compatibility issues, lead to performance degradation, and result in service unavailability. To prevent API failures, it is essential to address these factors by ensuring stable connectivity, robust security measures, scalable infrastructure, effective error handling, data compatibility, proper versioning strategies, performance optimizations, and contingency plans for service disruptions.

Bottom line

API integration holds tremendous potential for logistics providers, offering a pathway to smoother operations, streamlined data exchange, and improved customer satisfaction. For most of the LSPs, API is more suitable than EDI to provide data exchange. To see the difference, look through our blog post about EDI and API integration differences.

It’s crucial to steer clear of common API mistakes that can derail your progress and hinder your success. Based on your experience, we described the most common issues which occur when implementing API integration in logistics. And they frequently require a reliable IT outsourced partner to cover all issues while your IT department focuses on infrastructure maintenance.

Need an IT vendor for API implementation with experience in logistics? Contact us to learn how we could help.

Category:

Category:  Tags:

Tags: