7 IT Trends in Warehousing: What to Keep in Mind in 2024

- 7 Game-changing trends in warehouse management

- 1. Wearables and smart warehousing equipment through API integration

- 2. On-demand warehousing

- 3. Advanced automation and robotics

- 4. RFID evolution

- 5. Internet of Things beacons

- 6. Immersive reality

- 7. 3D printing

- IT warehousing FAQ

- Afterthoughts

Advances in digital technology are revolutionizing the way companies manage their warehouses. A crucial component of the supply chain, the warehousing industry is a fundamental contributor to the success of many businesses. From medium-sized companies to large enterprises, organizations rely on their storehouses’ capabilities to keep, manage, track, pack, and deliver their stock. The efficiency of these underlying processes determines their competitive advantages.

The global warehousing and storage market volume has reached $714.79 billion in 2023 compared to $660.39 billion in 2022. Effective warehousing is intertwined with the adoption of digital technology. Thus, the market size of storehouse automation is projected to increase from $13.46 billion in 2020 to $30.85 billion in 2026, while advanced automation is only one of the new innovations in warehousing.

Therefore, regardless of the business you are in, if your product assortment goes through a warehouse at a certain stage, keeping an eye on emerging trends is significant.

We compiled a list of seven promising new trends in warehousing that are likely to shape the future of this sector and outlined the companies developing cutting-edge IT techs and applying them in their daily operations.

7 Game-changing trends in warehouse management

Numerous exciting technical novelties aim to enhance warehousing administration, advance automation, expedite storehouse speed, and enhance safety. Let’s overview seven emerging trends in warehousing and how companies apply them in their operations.

1. Wearables and smart warehousing equipment through API integration

Storehouse operators continually deal with decentralized environments and tough schedules. Nevertheless, they need to perform their assignments efficiently. To attain this goal, they require a capacity to move around freely and seamlessly. One of the latest trends in warehouse management, which is smart warehousing equipment, comes at their service. Smart wearable devices grant hands-free mobility and deliver compelling information about products in a warehouse. Smart glasses or intelligent gloves are illustrative examples of such wearables that improve employee productivity and enable them to fulfill actions with the proper posture.

Coreteka: A software developer creating smart warehousing equipment

Our team provides smart warehousing services. Recently, we developed an Android-based mobile application, allowing the LSP to connect their Warehouse Management System with workers’ devices. This solution provides warehouse staff with detailed instructions. For example, they can receive notifications on what SKU to pick and from what storage cell. We also created a mobile application with a back-end server-side integrated with the client’s WMS.

Amazon: An active user of smart wearables

One of the largest global marketplaces, Amazon, has explored the use of wearables in its warehouse operations. To improve navigation through their giant warehouses, the company has tested wristbands that use haptic feedback to guide workers toward the correct bin locations during the picking process. The wearable vibrates to indicate the correct bin, improving accuracy and efficiency.

AGADE: The manufacturer of exoskeletons

An enthralling example of a smart wearable device is exoskeletons crafted by the Italian startup AGADE. These products assist operators in manual material handling. The manufacturer uses proprietary technology to make their exoskeletons adaptable for proper compensation of physical effort applied by users according to their movements and payloads. Therefore, the devices amplify users’ efforts and relieve their muscle stress. Ultimately, storehouse workers become empowered to operate heavy inventory without extra strain.

2. On-demand warehousing

On-demand warehousing is a model where businesses can quickly and flexibly access additional warehouse space and services on a temporary basis. In fact, it is an online marketplace providing warehousing and logistics services without long-term commitments. On-demand solutions grant the ability to scale a company’s storage and distribution capabilities without the hassle and costs associated with getting traditional leases or owning their own warehouses.

On-demand warehousing platforms typically connect businesses needing space with warehouse providers who have available capacity. These platforms act as intermediaries, facilitating the process of finding, booking, and managing temporary warehousing arrangements.

Wareteka: The first dedicated platform for all warehousing operations

Coreteka is proud that our team participated in the development of Wareteka–the largest warehouse database in Ukraine. This platform contains thousands of proposals to help businesses find the storage facility that suits their requirements most of all. The marketplace allows for selecting warehouses by options, obtaining a partner to outsource logistics operations, and controlling storehouse work online.

We have also developed a special service, WareTeka Online Workspace, to simplify cooperation with 3PL operators. The service streamlines interactions with 3PL operators, grants users complete control over their operations through personal accounts, enables inventory accounting, and provides convenient integrations with a wide range of ERP and storehouse WMS through API.

The platform’s functionality opens opportunities for small to medium businesses to cooperate with top warehousing providers and boost the efficiency of their warehousing and logistics operations.

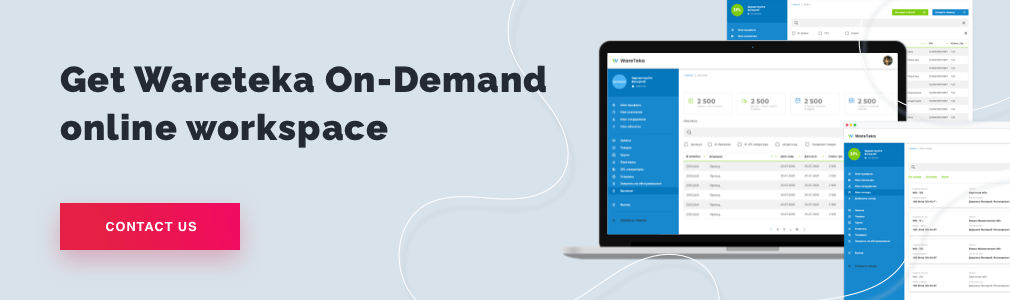

3. Advanced automation and robotics

Warehousing processes are typically labor-consuming. By employing autonomous mobile robots, organizations reduce labor intensity at their jobs. The trends in warehouse robotics include technologies like automated guided vehicles (AGVs), robotic picking systems, and autonomous drones, which improve efficiency, reduce errors, and speed up operations. Furthermore, companies raise their personnel’s and inventory’s safety by automating inventory picking, palletizing, and transportation.

Ware: A startup manufacturing autonomous drones

Ware is an American company that creates autonomous drones flying within warehouses. These smart machines utilize indoor geolocation technology, AI to bypass obstacles, and a scanner to take inventory images and shape a digital replica of the warehouse. The solution allows scanning barcodes and recording product location data to store it in the cloud for further analysis. Ultimately, the drones digitize the facility, which expedites warehouse product recording.

DHL: An example of extensive automation

DHL, a global logistics and shipping company, has embraced automation in its warehouses. They utilize robotics, AGVs, and automated sorting systems to enhance their supply chain operations. DHL has also explored technologies like collaborative robots (cobots) to work alongside human workers in various tasks, including order picking.

4. RFID evolution

Radio-frequency identification is a technology that enables automated data collection. Although the technology itself is not one of the most recent trends in warehousing, it has lately undergone remarkable upgrades. The shrinking tags and increasing memory expand the possible use cases. Together with the opportunity to reuse certain types of RFID tags, this makes the tool eco-friendly and budget-saving.

How does the tech work? RFID readers accumulate information from tags at a larger distance, which is practical for huge warehouses. The resulting traceability is useful for the supply chain in many aspects. The tool helps to locate items and track parcels from the distribution center to the destination point. The systems utilizing RFID technology significantly transcend traditional barcode systems in terms of accuracy and data volume.

Delta Air Lines: RFID helps to reduce luggage losses

Delta Air Lines utilizes RFID technology in its warehouse and cargo operations to improve the tracking and management of baggage and shipments. Baggage tagging, automated scanning, and real-time tracking allow the company to monitor and manage the location of bags, ensuring they are routed correctly and loaded onto the proper aircraft. The RFID system identifies the destination of each bag, ensuring it is sorted and loaded onto the appropriate flight. Besides, RFID tags on bags are used during the load verification process. RFID readers installed on loading equipment confirm that the correct bags are loaded to specific aircraft, reducing the risk of mismatches and improving load accuracy.

5. Internet of Things beacons

One of the powerful technology trends in warehousing is IoT, which helps to control and optimize stock-related operations. The systems based on this technology comprise connected sensors tracking items throughout the warehouse and control parameters such as lighting, temperature, moisture, and more. IoT tools leverage real-time data from beacons to enable stock management and analytics. Smart shelves transfer inventory information and identify when the units need replacement. Another IoT-backed solution, digital twins, derives information from the storehouse network and WMS to make a real-time warehouse model. Such a model aids managers in visualizing operations, searching for pieces, and simulating changes to the layout and working process.

ScratchNest: A manufacturer of tracking beacons

ScratchNest is an Indian startup that creates a small IoT beacon with extended battery life for user location tracking. Supported by Bluetooth low energy technology, this wireless transmitter passes signals to users’ smart devices, empowering operators to identify the location of inventory and personnel easily.

DHL and IoT implementation

DHL has integrated IoT sensors in its storehouses to monitor and track various aspects of warehouse operations. These sensors are used to collect data on factors like temperature, humidity, light, and movement to ensure optimal storage conditions, track inventory in real time, and detect any anomalies or issues that may arise. IoT sensors significantly enhance managing the giant storehouses of the global logistics company.

6. Immersive reality

Proper equipment is only part of the story when it comes to the fast and accurate movement of items within a warehouse. The success of these processes largely relies also on personnel skills. This leads us to another new trend in warehousing: virtual and augmented reality (VR/AR) implementation. Storehouses are integrating immersive reality solutions to elevate the efficiency of their employees. The tools simplify numerous procedures such as warehouse growth planning, predictive modeling, and arranging delivery processes.

How can virtual reality reinforce employee skills? By providing immersive training in warehouse assignments. AR is applied in product search processes, as it can quickly lay out the optimal route to a specific product.

Ultimately, both technologies can visualize operations to facilitate the decision-making process.

EHS VR: A startup that created VR Forklift Training

EHS VR, a UK-based startup, supports the immersive reality trend by developing a platform for training storehouse teams. The company offers VR-based forklift training to teach warehouse employees to work with forklifts. The solution controls and reports the employees’ progress throughout the learning period. The training is personalized and does not depend on the availability of free equipment.

GE Appliances: The immersive reality in action

GE Appliances, a division of General Electric, has implemented augmented reality in its warehouse operations. They utilize AR headsets to guide workers when locating and picking items. The headsets overlay digital information, such as item locations and quantities, on top of the physical environment, aiding workers in navigating the warehouse and optimizing picking efficiency.

7. 3D printing

3D printing is an exciting technology that can bring fruit to many industries, including the warehousing sector. It offers versatility and agility in manufacturing customized objects and reduces the need for large inventories of parts and products. In particular, it is leveraged for prototyping, customized packaging and labeling, tooling for warehouse operations, tailored equipment for facility upgrades, and more. The technology allows producing complex objects in a cost-efficient and time-saving manner.

Rize/Palitra: The producer of exclusive 3D printers

Rize (currently, Palitra) offers 3D printers designed for creating functional parts, tooling, and fixtures. Their printers feature unique capabilities, such as augmented polymer deposition and minimal post-processing requirements, which can be beneficial in warehouse environments.

BMW: 3D printers for scarce spare parts production

BMW has implemented 3D printing in spare parts production for classic and vintage car models. By utilizing 3D printing technology, BMW produces discontinued or hard-to-find spare parts upon request. Therefore, the manufacturer reduces lead times and inventory costs while ensuring the availability of parts.

General Electric: A vast application of 3D printing

General Electric has utilized 3D printing technology in its aviation and healthcare divisions. In warehouses, 3D printers produce customized components for engines, turbines, and medical devices. Furthermore, GE leverages 3D printing for creating customized tools, jigs, fixtures, and product customization. Ultimately, the enterprise improves efficiency, accelerates innovation, and enhances supply chain management with the help of 3D printers.

IT warehousing FAQ

Information technology (IT) is utilized in warehouses for efficient management and optimization of processes. The application areas include inventory management through real-time tracking, automated systems, optimized workloads, and safety. IT controls and coordinates advanced automated systems, including conveyor belts, robotic arms, and automated guided vehicles (AGVs), improving material movement. IT also enables cloud computing, IoT devices, mobile technologies, and integration to enhance connectivity, scalability, and accessibility in warehouse operations.

The latest technology trends in warehousing include smart warehousing equipment that streamlines tasks and improves storage. On-demand warehousing enables better access to extra storehouse space. Robotics and automation solutions, such as robotic arms, autonomous mobile robots, and automated guided vehicles, facilitate material handling and improve productivity. Internet of Things devices like sensors and RFID tags help to track assets, monitor environmental conditions, and collect real-time data. Augmented reality and virtual reality technologies bring value to training and maintenance tasks, enhancing worker efficiency and safety. Drones are also being explored in the field of inventory management and warehouse inspections, providing faster and more accurate data collection.

Smart warehouses apply technologies like the Internet of Things (IoT) for real-time data collection, automation and robotics for streamlined processes, and AI and ML for data analysis and optimization. Additionally, smart warehousing equipment including wearable devices, augmented reality (AR) and virtual reality (VR), cloud computing, and predictive analytics play key roles in enhancing warehouse efficiency, connectivity, and decision-making.

Amazon warehouses are at the forefront of advanced technologies. They utilize robotics and automation, with autonomous mobile robots (AMRs) and robotic arms assisting in inventory movement and order-picking tasks. Amazon has developed its own warehouse management system, known as the Amazon Robotic Fulfillment System (ARFS), to optimize workflows and coordinate the movement of inventory and robots. Artificial intelligence (AI) and machine learning (ML) technologies find their extensive use in demand forecasting, inventory management, and operational optimization.

Afterthoughts

The new innovations in warehousing boost operational efficiency and informed decision-making. Multiple companies and startups worldwide are pushing the limits of warehousing technology solutions to reinvent storehouse management and transform the whole industry. Intelligent robots, WMS, AR/VR solutions, AI-powered tools, IoT, and smart wearables are some of the modern trends in warehousing that many industry players already adopt, and more is yet to come.

Breakthrough solutions reduce the labor intensity of tasks, elevate employee safety, expedite routine jobs, and drive productivity. With the growing complexity of warehousing operations, advanced tools keep adapting to the ever-changing environment and become even more worker-friendly.

To retain a competitive edge, you should keep pace with emerging techs and be able to identify new opportunities. Professional software developers like Coreteka are well-versed in the latest advancements in warehousing technology. We know how to harness these techs for maximum use in each specific case. Why? Because we work with them every day and already have a successful track record of their application.

Contact us to bring your warehousing and logistics operations to the next level.

Category:

Category:  Tags:

Tags: