WMS Power Unlocked: API Integration Best Practices & Coreteka Cases

- WMS data exchange: a detailed look at why it’s challenging

- How can WMS API integration enhance interaction between 3PLs and their customers?

- Warehouse management system integration: Coreteka use cases

- Use case #1: WareTeka On-Demand Platform: the ready-made tool

- Use case #2: WMS integration with ERP

- Use case #3: WMS API integration with marketplaces and eCommerce platforms

- Use case #4: Intelligent analytics

- Use case #5: Smart warehouse equipment

- Last Mile Connector Coreteka case study: in search of unique approaches

- How much does it cost to integrate WMS with other systems through API?

- Frequently asked questions about WMS API integration

- Conclusion

Warehousing order management is a headache for logistics companies and their clients. 3PL providers know how time-consuming and daunting managing multiple goods can be. Customer convenience is the other side of the coin. They should clearly understand their material flows, from the number of orders to stock levels.

Thanks to IT solutions, order management becomes easier for both parties. Modern Warehouse Management Systems (WMS) allow LSPs to completely control their operations like material handling, inventory management, and fulfillment. At the same time, the question of data exchange between logistics providers and their clients is still open. How can they ensure that all necessary information gets into WMS promptly and flawlessly? Here is where technology helps too.

Logistics providers can connect their Warehouse Management Systems with the clients’ software via API (Application Programming Interface). In our blog, we recently described how this works for Transport Management Systems. If you’re interested in the topic, look through our blog post. Here, you can also find a detailed explanation of what is API.

So, what about incorporating API in Warehouse Management Systems? In this article, you will find out how API integration can simplify data exchange between 3PLs and their clients, explore different options, and get real case studies from Coreteka. Read on!

WMS data exchange: a detailed look at why it’s challenging

Let’s look at how sending information to 3PLs looks from a client’s size. In most cases, data exchange occurs manually, through file sharing. This is a typical situation for small- and mid-sized businesses.

The process looks like this:

- The client sends orders each time when they need such services. The request should be received in a special format, allowing the provider to enter data into WMS properly.

- When there is a need for goods shipment from a warehouse, the client also must send a request manually.

- Every day, the client gets a file that contains information about stock levels.

But what’s the problem? The thing is that in such cases the data exchange process is not seamless. Moreover, if the client works with several logistics providers, it can be hard to adapt files since every logistics provider has its unique format. There is also no clear visibility. This is terribly uncomfortable. Logistics providers also suffer because error risks are too high when it comes to manual data entering into WMS.

WMS API integration resolves this issue.

How can WMS API integration enhance interaction between 3PLs and their customers?

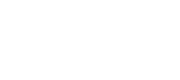

API integration refers to connecting Warehouse Management Systems with other software. For example, Enterprise Resource Planning and Content Management Systems. This helps different systems to work together seamlessly, providing real-time information and automating processes for better accuracy and efficiency.

Find out what benefits WMS API integration can deliver for logistics providers:

| Process | Improvement |

| Order management | WMS API integration can provide customers with real-time tracking information for their orders, allowing them to monitor the status of their orders and adjust their plans as needed. This can help improve customer satisfaction and reduce the workload on 3PL customer service staff. |

| Order processing | Through API integration, it’s possible to automate the order processing and fulfillment process, allowing customers to place orders directly through the WMS and reducing the likelihood of errors. This can help improve order accuracy and reduce order processing time. |

| Inventory management | After connecting WMS with other systems via API, your customer can get real-time inventory updates. This will help them better manage stock levels and accurately plan orders. |

| Client communication | WMS API integration reduces the need for manual communication and improves efficiency. For example, customers can receive automatic notifications when their orders ship or when inventory levels change. |

As a result, logistics providers can significantly enhance their customer service and avoid operational mistakes due to human factors.

Warehouse management system integration: Coreteka use cases

There are no businesses that run the same way. That’s why we should search for different approaches in each specific situation. For example, your client may have no resources and desire to make such complex manipulations. Or, their software and goals can be different. Let’s explore what options our team can propose.

WareTeka On-Demand Platform: the ready-made tool

Small businesses aren’t ready to invest in costly solutions due to a lack of financial resources. However, they suffer from manual order management and endless filling in applications. Coreteka has a great solution in such a situation.

Our team has developed an out-of-the-box platform, called WareTeka On-Demand. This solution allows you to:

- Manage warehouse shipments in real-time.

- Get actual data about order processing status.

- Monitor stock levels in the partner’s warehouse in real-time.

- Conduct electronic document flow.

Since WareTeka On-Demand is a ready-made solution, all you need is to drop us a line and agree on configuration according to your business processes.

WMS integration with ERP

Enterprise Resource Planning (ERP) systems are the privilege of large businesses, allowing them to manage all operations in one place. However, when outsourcing logistics, Warehouse Management Systems and ERP software should be connected to operate as a single whole.

After integrating WMS and ERP, there will be one more module for a client — the third-party warehouse. This way, 3PLs’ customers can directly manage their storage, orders, shipments, and fulfillment directly from ERP. Nonetheless, this solution fits only large businesses that already have Enterprise Resource Planning software.

You can also explore more about ERP systems integration in our blog post.

WMS API integration with marketplaces and eCommerce platforms

Logistics providers’ clients frequently work in the B2C sector. In most cases, their work is based on marketplaces and eCommerce platforms. Moreover, giants in this industry like Amazon, Shopify, and eBay already provide customers with order management options directly from their platforms. It’s possible to manage order delivery and stock levels without any integrations. On the other hand, if a company collaborates with a logistics provider, its outsourcing partner can’t access needed information. So, there is a challenge of data exchange again. Customers are forced to convey information about orders through the file and email sharing while they already have the necessary configuration on eCommerce platforms.

To simplify order and inventory management in such cases, Coreteka can integrate a logistics provider’s WMS with marketplaces and eCommerce platforms. We work with Shopify, Magento, WooCommerce, WIX, AliExpress, Etsy, Allegro, Amazon, eBay, and other popular solutions.

Intelligent analytics

WMS API integration can do a great job when it comes to business intelligence. This works like this: needed information is gathered in Warehouse Management System, then it’s transferred to analytics systems and can be processed. 3PLs can gather data on their supply chain operations and use this information to make informed decisions.

For example, you can monitor the stock levels of each specific client, order fulfillment rates, shipping times, and other KPIs. After analyzing this data, it’s possible to identify trends, improve efficiency, and reduce costs.

Intelligent analytics can also help businesses to identify potential issues before they become major problems. For example, if inventory levels are running low, the system can automatically generate alerts and notify the appropriate personnel to take action.

Coreteka can integrate your WMS with Oracle Business Intelligence, Qlik, Power BI, and Google Data Studio solutions.

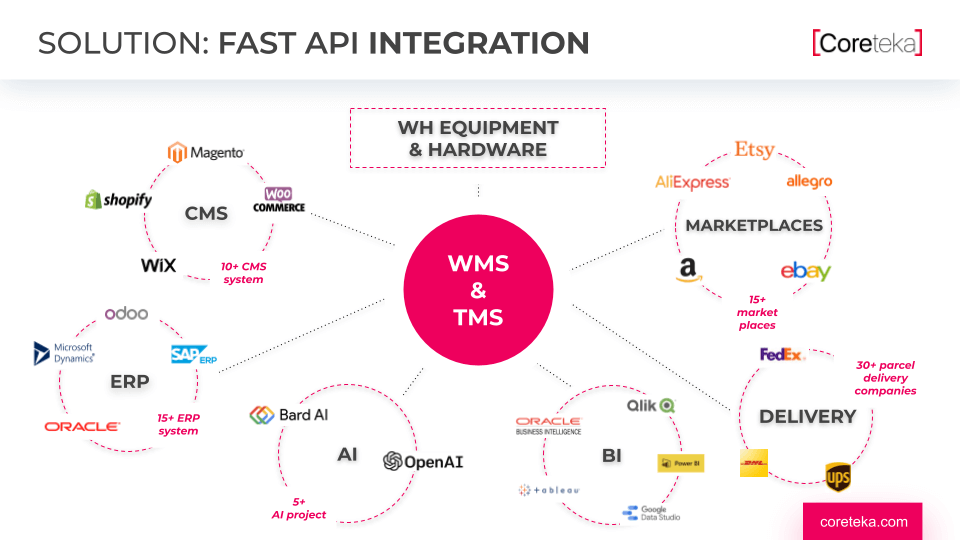

Smart warehouse equipment

Since warehousing is about complex and intricate operations, staff can make a lot of mistakes, from choosing improper SKUs to non-productive movements. This can be eliminated by automating your storage facilities.

Warehouse Management Systems can be integrated with warehouse equipment, such as assembly lines and order-picking devices. After integration, your WMS can give hints to warehouse staff and control hardware.

Coreteka implemented this solution for one of our clients. Now, the company’s warehouse workers receive detailed instructions on what SKU to pick and from what storage cell. All information is conveyed through wrist-worn scanning devices. We also developed a mobile application that has a back-end server-side and is integrated with the client’s WMS.

You can contact us to implement something similar in your warehouse.

Last Mile Connector Coreteka case study: in search of unique approaches

WMS API integration should meet specific needs and resolve challenges for businesses. That’s why it’s necessary to search for unique approaches when it comes to warehousing. We’d like to tell you about one of our case studies — Last Mile Connector.

Project description

A food supplements manufacturer, operating in the B2C landscape and selling products through marketplaces, decided to outsource its logistics to an LSP. At the same time, last-mile delivery services were handled by a third-party courier company as a part of this collaboration. The LSP approached us to connect its WMS with the courier company’s TMS which will allow them to automate the process of creating last-mile delivery waybills.

Challenge

Before integration, electronic waybills had to be created manually. This, in turn, led to a large number of errors. Moreover, the number of parcels was really large so it was challenging for LSP to process orders quickly and properly.

Solution

The integration allowed the logistics provider to create electronic waybills automatically and receive real-time status updates from the courier company’s TMS into their own WMS, In such a way, the LSP can be informed about the current delivery stage for each parcel, enabling them to pass this information on to their client.

In simple words, Last Mile Connector became a gateway between the Warehouse Management System of the logistics provider and the Transport Management System of delivery service. The platform also has its own server side. You can read more about Last Mile Connector in our article.

How much does it cost to integrate WMS with other systems through API?

As we mentioned earlier, there are no one-size-fits-all solutions in API integration. Therefore, the WMS integration price will be different in each specific situation. Key factors that form WMS integration cost are complexity, the number of systems being integrated, customization level, and specific API features.

It is important to note that the integration cost may also depend on the specific vendor or solution. Some vendors offer pre-built integrations or APIs that can make the integration process faster and more cost-effective. Others may require more custom development work.

Consult with a WMS integration specialist to get a more accurate cost estimate, based on the specific requirements of your business. You can describe your needs in the website form, and Coreteka technical specialists will send you detailed WMS integration pricing.

Frequently asked questions about WMS API integration

An API, or Application Programming Interface, enables different software applications to communicate and exchange data with each other. In warehousing, APIs are typically used to allow other software systems, such as an Enterprise Resource Planning (ERP) system, a Transportation Management System (TMS), or a Customer Relationship Management (CRM) system, to access and interact with data in the WMS. This can include retrieving inventory data, sending orders to the WMS for fulfillment, or updating shipment information.

APIs in a WMS can be designed to be either inbound or outbound. An inbound API allows external systems to send data into the WMS, while an outbound API enables the WMS to send data out to other systems.

API serves as a doorway between Warehouse Management Systems and other software. In such a way, it lets you access the information. Data exchange operations can be different depending on the specifics of the WMS providers. You can get detailed instructions from them.

Warehouse Management System can be integrated with the Enterprise Resource Planning system. In this scenario, the WMS would manage the inventory and order fulfillment processes in the warehouse, while the ERP system would handle the business management processes, such as accounting and procurement. Through API integration, the two systems can communicate and share data in real time, providing better visibility and control over the supply chain.

For example, when a customer places an order through the ERP system, information about it can be sent to the WMS through an API. The WMS can then use this information to pick up the items from the warehouse and prepare them for shipment. The WMS can also send back information on inventory levels and order status to the ERP system through the API, providing real-time updates on the order fulfillment process.

Conclusion

Warehouse Management Systems are an indispensable tool for logistics providers. With features such as inventory management, order fulfillment, and real-time tracking, WMS can help 3PLs achieve greater efficiency, accuracy, and visibility in their warehouse operations.

However, to fully realize the benefits of a WMS, you should ensure it is integrated with key systems of your clients, such as ERP, TMS, CRM, CMS, and so on. The API integration can help achieve this by enabling seamless communication and data sharing between systems.

Coreteka has 7+ years of experience in developing IT solutions for the logistics domain. In these years, we successfully assisted our clients in API integrations and build relevant tech products that are based on specific requirements and goals. For example, we developed the WareTeka On-Demand platform. It allows small-sized businesses quickly exchange information regardless of their warehousing operations with 3PLs. The solution is ready-made, allowing it doesn’t require complex integrations. Our team also automated the client’s warehouse and made Last Mile Connector, the solution which connects TMS and WMS.

Want to discuss your project with us? Feel free to contact us.

Category:

Category:  Tags:

Tags: